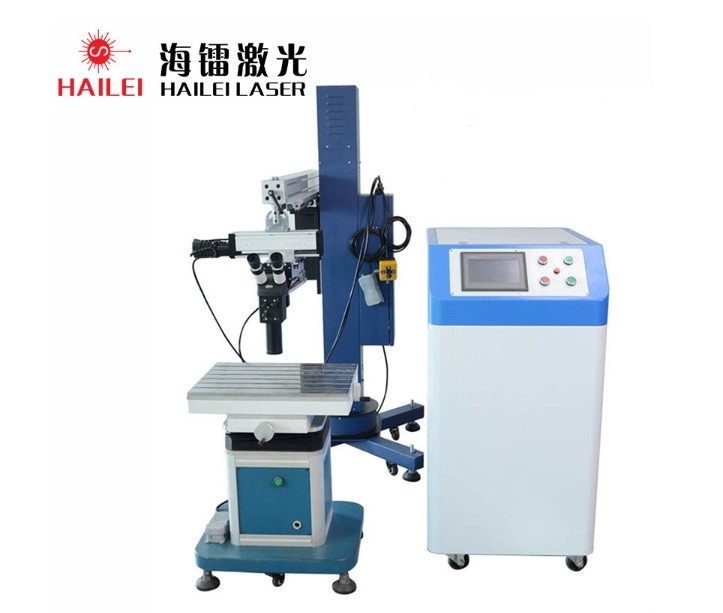

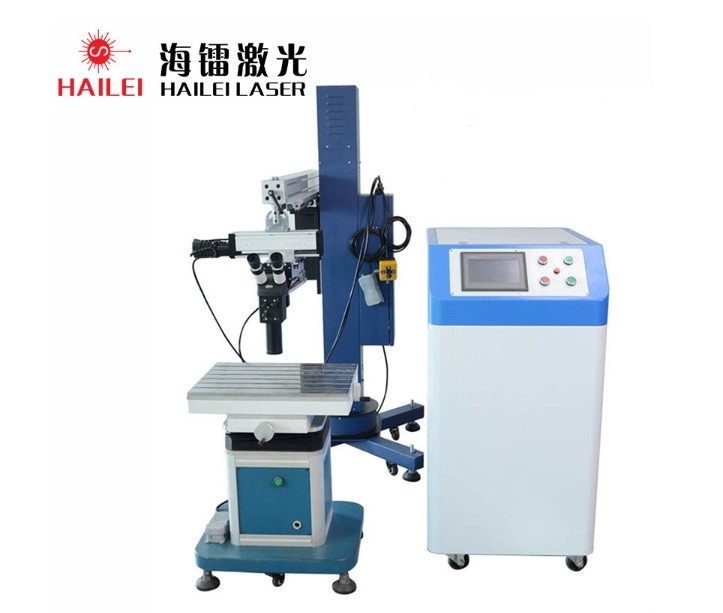

200W Cantilever Mold Laser Welding Machine With Boom System Repair

And Weld Metal

Characteristics of Mold laser welding machine:

Mold laser welding machine is a new type of welding processing,

mainly for thin-wall materials of precision parts welding, can

achieve butt welding, sealing welding, spot welding, overlap

welding, etc., weld width is small, depth to width ratio is high,

heat affected zone is small, deformation is small, welding speed,

smooth weld, beautiful, no need to deal with or only simple

treatment after welding, weld quality is high, no porosity, welding

speed is high. Precise control of positioning accuracy, small focus

point, easy to achieve welding automation.

Product Features:

1, 10 directions to flexibly adjust the welding Angle position,

suitable for a variety of mold welding.

2. For large molds, mold welding can be carried out directly on the

ground or forklift without workbench.

3, with high-power split chiller and high-power laser chamber,

long-term, high-power welding, better stability.

4, the use of British ceramic cavity, high reflectivity, long

service life.

5, table base electric lifting, table moving using precision ball

screw and high precision straight guide rail light and flexible,

accurate positioning.

6, the laser head can slide back and forth, manual lifting, the

laser head can easily rotate 360 degrees, easy to repair welding

any side.

Technical parameter

| item | Item parameter |

| Product model | HL-MD-200W~400W |

| Maximum laser power | 200W~400W |

| Laser wavelength | 1.064 (um) |

| Maximum energy of a single pulse | 90J |

| Laser welding frequency during combo | 0.1 Hz ~ 15 Hz |

| Laser welding depth | 0.1 mm to 3.5 mm |

| Pulse width | Ms 0.5 ~ 20 ms |

| Laser welding working distance | 0.2 nm ~ 2 mm |

| laser | 0.2 mm to 0.8 mm |

| Spot size adjustable range | Enhanced automatic workbench, optional electric workbench |

| Operating voltage | <11KW |

| Water pressure protection | Single-phase 220V15%VAC50Hz40A or above |

| Cooling water temperature | 220 volts 50HZ AC, providing more than 30 amps of current (6 square

meters), voltage stability. |

| workbench | Three-dimensional workbench, |

| Use environment | Clean no dust or less dust, temperature :55°F13~82°F28 ° C,

humidity :5%~75% no condensation |

| Observation system | Stereo microscope with cross cursor, welding position magnification

10x (optional 15x, 20x). Align the center of the cross cursor with

the center of the laser spot. With high speed liquid crystal light

valve filter protection device to protect the eyes of the welder

from fatigue due to laser flicker. |

| Control system | Industrial microcontroller real control, high stability, easy

maintenance. |

| Gas protection system | The automatic synchronous argon protection system ensures that the

welding parts will not be oxidized and discolored. |

Application Fields:

The Mold laser welding machine is specially designed for the laser

welding of super large molds, such as automobile molds, shell

molds, tire molds, plastic shell molds of home appliances and other

large plastic and die casting molds. This machine is equipped with

a boom system can be lifted up and down, 360 degree rotation, can

repair welding radius of 1.5 meters, weight of several tons of

large molds, and this equipment is equipped with pulley, easy to

move, can be moved to the injection molding machine directly repair

welding, without removing the mold.

Can repair welding of course also suitable for small and

medium-sized mold repair.

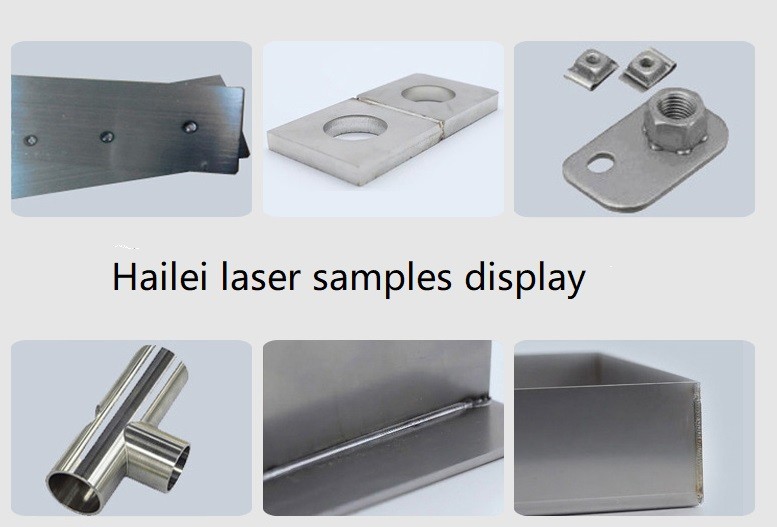

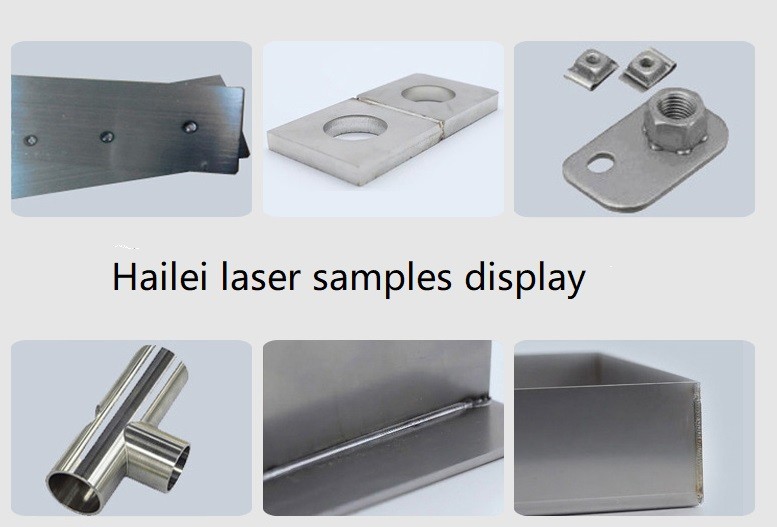

Sample Display(Parts Sample)

Profession and Honor

About this product,we also support customized services,If you would

like to know further product information and requirements, please

contact us online or send E-mail to us.Thank you for your time!